How Augmented Reality Is Changing Manufacturing

Augmented Reality is transforming the landscape in several industries, most noticeably in healthcare, education, training, retail and manufacturing. Although still in the early phases, AR has already proved itself extremely valuable to these industries in terms of practical use and the implementation of AR for everyday activities will only increase in the years to come. A report from Greenlight Insights says that: “In the five years to 2023, consumer and commercial spending on AR content and software is forecasted to grow at an average annual rate of 78% to $15.4 billion.”

Manufacturing practices in particular can be greatly improved through the introduction of AR technology. Augmented reality is already playing a significant role in the improvement of productivity, efficiency, and safety in manufacturing plants.

AR For Productivity

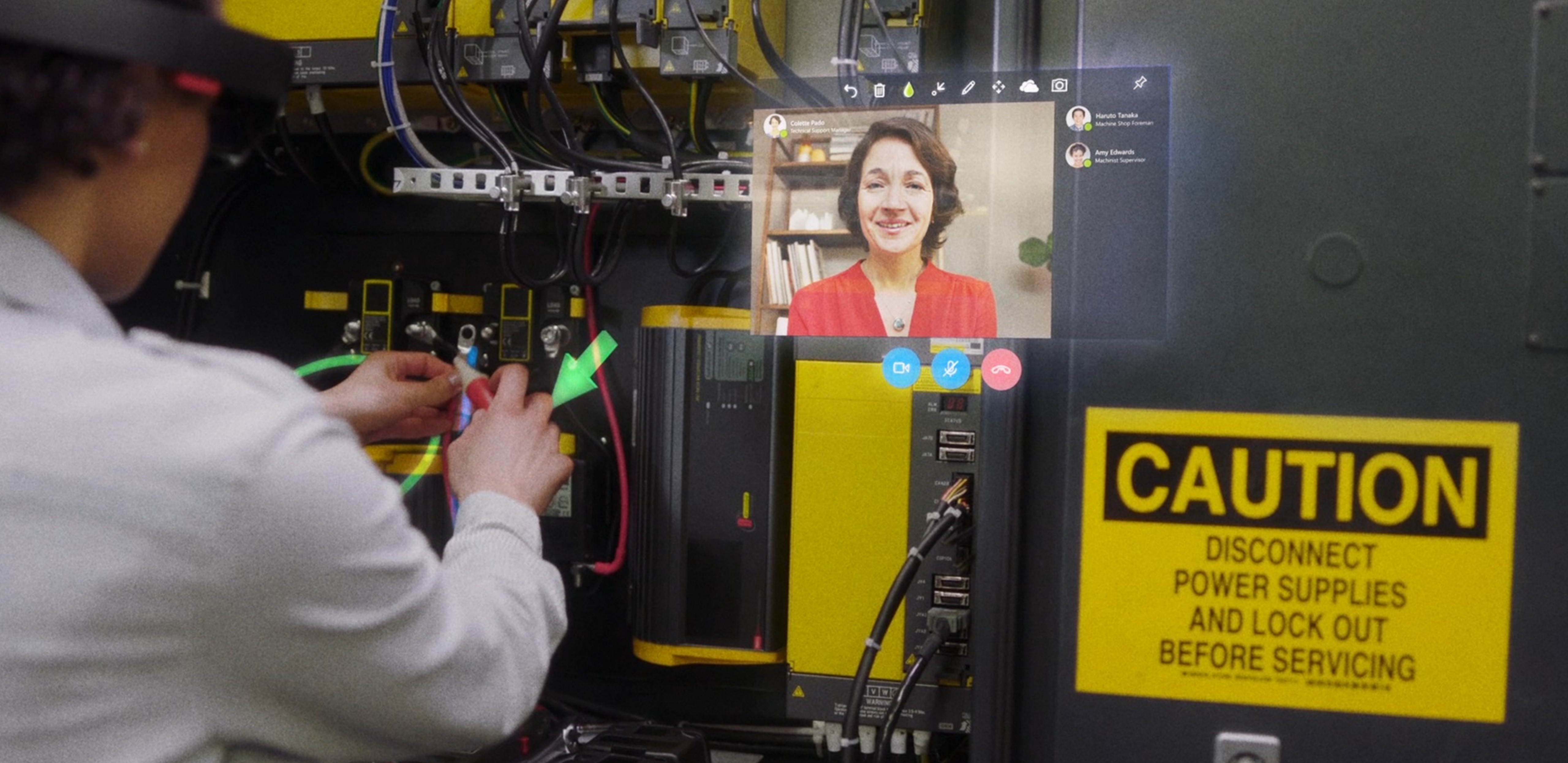

Industrial plant personnel can have hands-free access to digital information and video files that can aid in everything from inventory checks to complex maintenance and troubleshooting of factory equipment. Wearable AR devices such as the Microsoft HoloLens already have the capabilities to deliver this data to users. Instead of true augmented reality, the HoloLens offers a Mixed Reality (MR). This MR blends the physical and digital worlds by allowing the user to see and interact with their real world environment with overlapping digital content and information.

This information is delivered within the user’s line of sight, leaving them free to complete the task without having to stop and refer to any manuals or instruction sheets. A study by GE found that a worker carrying out a task using a wearable AR device was 34% more productive than they were doing the same job but using a paper-based manual as a guide.

AR For Logistics

Augmented reality technology has the potential to increase productivity in warehouse operations as well as transport and delivery tasks. The information being pushed into the eye-line of the user in real time makes for easy identification of physical objects e.g. parcels in a warehouse. The instant feedback and recognition of objects provided to warehouse workers can significantly reduce the time spent organising stock. The current methods deployed in most warehouses involve traditional paper checklists and stock takes. These methods are slower and more prone to human error than the solution provided through augmented reality systems.

“AR has so far shown most promise for logistics in warehousing operations. These operations are estimated to account for about 20% of all logistics costs, and the task of picking accounts for 55% to 65% of the total cost of warehousing operations. This indicates that AR has the potential to significantly reduce cost by improving the picking process” – DHL.

Delivery drivers’ productivity can also be significantly increase through the use of AR. Much of the time it currently takes to transport goods is spent loading and unloading the packages from freights.

“Estimates suggest that drivers spend between 40% and 60% of their time away from the distribution centre not driving. Instead, they spend much of this time locating the correct boxes within their truck for the next delivery. Currently, to find a box, drivers must rely on their memory of the loading process.” -DHL

AR For Training & Up-skilling

The ability to have in-depth and real-time instructions appear in the users’ field of view, while keeping their hands free to carry out tasks, means that AR can dramatically improve the skill-set of workers while on the job.

Utilising AR for the training and up-skilling of workers means that every step of a procedure, such as repairing industrial equipment, is laid out on front of them and all safety measures are met while the work is carried out. Remote assistance with a more experienced employee can be provided through AR to keep the interpersonal aspect of training and add more detail to the lesson at hand. Workers are now taken through every aspect of a task that they previously wouldn’t have had the knowledge to complete or would have been unsure in their ability to safely attempt.

Workers’ job satisfaction levels can also receive a boost once they have completed a task they previously had little knowledge of, with far more ease than they expected. Lorraine Bardeen, General Manager, Mixed Reality Workplace at Microsoft recently said: “One of the things we think is most exciting is that Mixed Reality has been a breakthrough for workers themselves. There’s been a surprising amount of grassroots engagement with mixed reality workflows very early on. Workers quickly realise the power of first-person point-of-view computing, and real emotional engagement goes way up. Fresh ideas are allowed to bubble up. Workers think in 3D. They are spatial arrangement workers, as a result, their work experience, their moments of decision making, are not so easy for them to explain. The shared views the HoloLens enables has empowered workers and made them active participants in the digital workplace.”